- √Product

- Air cooled chiller

- water-cooled chiller

- Water cooled screw chiller

- Air cooled screw chiller

- Double screw type col

- Low temperature screw type col

- Explosion proof screw type col

- Low temperature cold water mac

- Laser cooling-water chiller

- Cold and hot integrated machin

- Water transport type mold temp

400hp water-cooled screw chiller

- 产品详情

- 产品参数

Product manual:

Air-cooled screw chillers using advanced production technology, excellent quality, compact structure, beautiful appearance can be widely used in plastic electroplating electronic manufacturing pharmaceutical chemical food processing refrigeration and refrigeration and other industrial establishments and hotels, shopping malls, office buildings and other civil buildings Air Conditioning System.

Unit features:

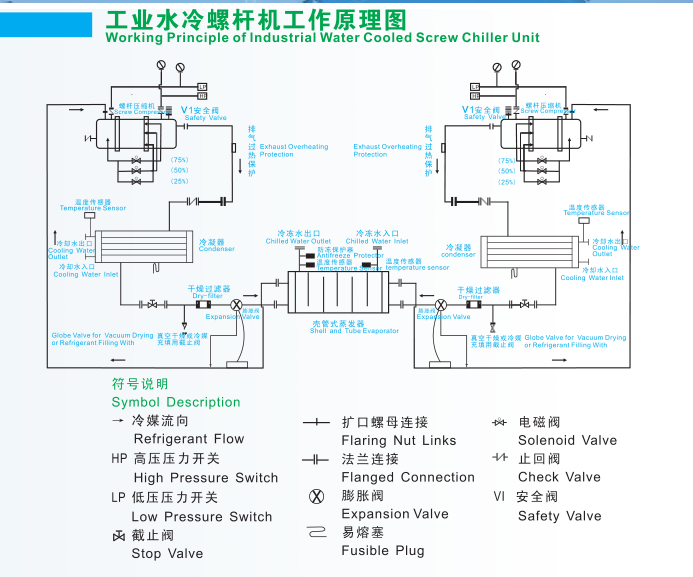

1, the use of imported international brands BITZER Germany (Bitzer) HANBELL China Taiwan (Han Chung) higher energy-saving compressor compressor match with high-quality condenser and evaporator, high efficiency, low noise, stable performance, long life. Industrial PLC unit centralized control, with the energy ratio of the compressor can be timely and accurate control unit cooling capacity and cooling load matching to ensure the best efficiency of the unit to run and reduce operating costs.

2, the internal integration of low-temperature water-free low-voltage lack of phase delay start anti-phase overload motor overheat oil pressure and many other security protection and processing functions.

3, the entire Chinese user interface, menu-style prompts, can be set to run the unit state, home appliances of the operating environment.

4, the capacity control can be four-stage (100% -75% -50% -25%) or three-stage (100% -66% -33%) and non-segment control system.

5, a unique built-in hydraulic system, no need to ensure that the compressor oil pump to maintain the best lubrication, oil separator with double-layer filter, oil filter effect, heat converter can play the maximum capacity.

6, high-performance internal thread brass, enhanced heat transfer effect, more energy-efficient higher education. The use of the latest CAD / CAM design and processing technology, CNC machining center production is completed, compact, small size 15. Durable. U-shaped structure of the heat transfer tube bundle, easy maintenance, to prevent leakage of refrigerant phenomenon.

7, the selection of all imported steel pipe, high-speed drilling and other professional equipment manufacturing, steel fins closer contact, heat transfer efficiency, with small size, light weight, the structure is more compact platform management and so on.